日期:2025-8-25 来源:科戈电子 cogo-tek.com

New Benchmark in Precision Measurement and Control | CPA Pressure Transmitter, the “Smart Brain” for Industrial Measurement and Control

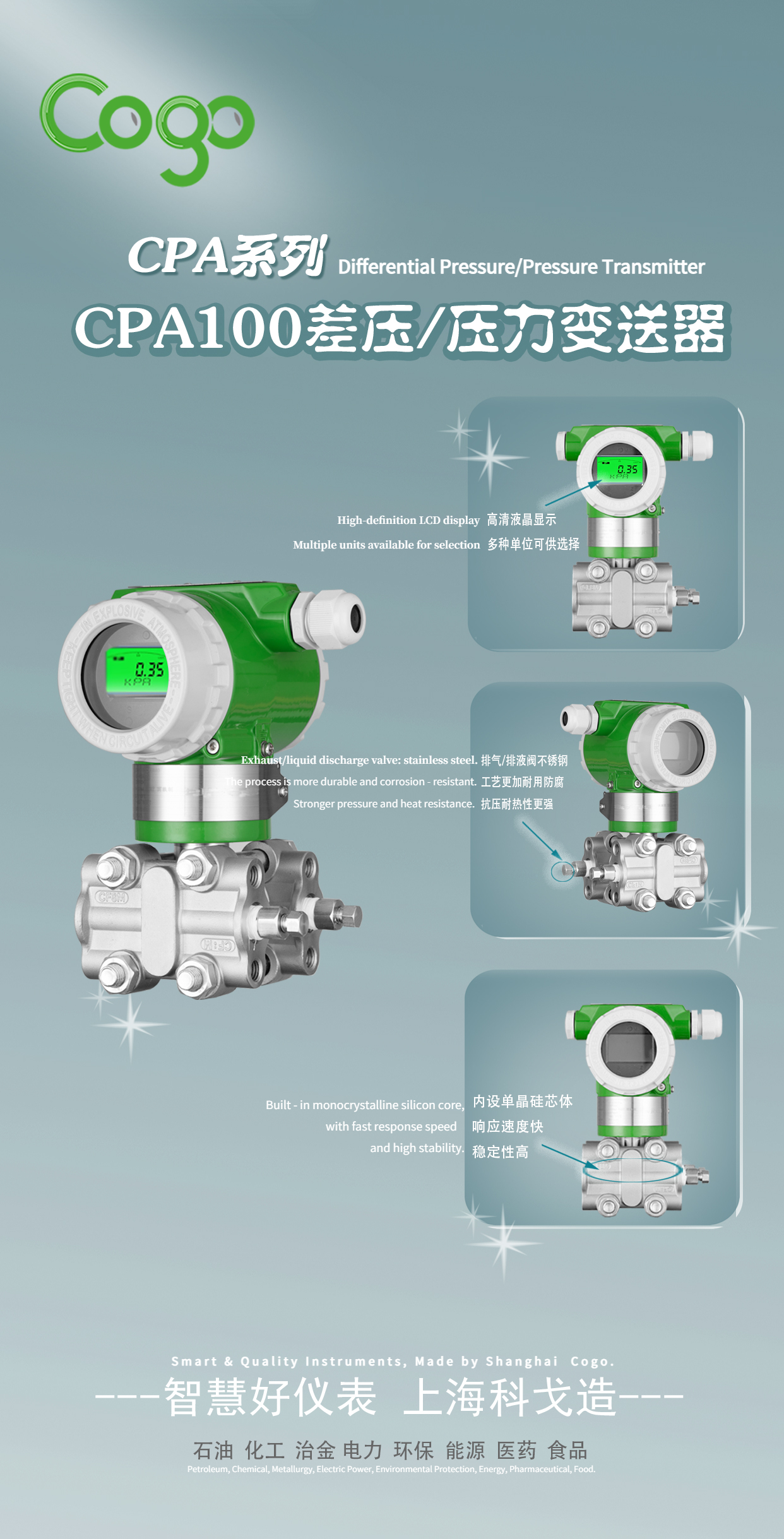

In the complex landscape of industrial production, pressure measurement and control is a crucial link in ensuring stable processes and accurate data. When the market is flooded with various transmitter products, the CPA Pressure Transmitter, leveraging its high-precision single-crystal silicon core, versatile adaptability, and durable and reliable performance, breaks through the bottlenecks of measurement and control. It serves as an intelligent “brain” for precise measurement and control in industries such as petrochemicals, environmental monitoring, food, and pharmaceuticals.

I. Single-Crystal Silicon Core: The Pinnacle of Precision, Zero Data Errors At the core of the CPA Pressure Transmitter lies a single-crystal silicon core. This “industrial heart” elevates the precision grade to ±0.075% and caps the maximum error at ±0.1% FS per year.

In the high-pressure pipelines of the petrochemical industry, it can accurately detect subtle pressure fluctuations, providing early warnings of potential pipeline leaks. In the sterile production workshops of the food and pharmaceutical sectors, its precise identification of minor pressure changes ensures stable parameters during processes like filling and sterilization, safeguarding product quality from the source. Zero data errors are its “assurance” for industrial production.

II. Flexible Adaptability: An “All-Rounder” for Multiple Scenarios, Seamless System Integration Industrial scenarios vary widely, but the CPA Pressure Transmitter excels as an “all-rounder”:

• Free Compatibility of Power and Signals: Adaptable to a 12–30VDC power supply (two-wire system), it outputs a combination of 4–20mA analog signals, LCD display, and HART protocol digital communication. Whether integrating with old industrial control systems or smart IoT platforms, it enables seamless connection, facilitating easy upgrades for both new and existing production lines.

• Customization for All Needs: With a measurable range from 100Pa (micro-pressure) to 3MPa (high pressure, customizable), capillary lengths of 1–10m (customizable), and process connections like DN50 PN16 (customizable). Whether monitoring liquid levels in deep tanks at environmental sewage plants or measuring pressure in high-temperature, high-pressure pipelines of steel mills, it can be tailored to the scenario, providing a specialized measurement and control solution.

III. Durable and Reliable: A “Tough Nut” for Extreme Environments, Reducing Operation and Maintenance Costs Industrial sites pose complex environments, and the CPA Pressure Transmitter demonstrates “reliability” through its materials and design:

• Corrosion Resistance and Durability: The diaphragm uses special alloys such as SUS316L/HC/TA/AU, and the flange is made of SUS304/SUS316L stainless steel. In harsh environments with acid-base corrosion, high temperatures, and high pressures, it boasts exceptional corrosion and deformation resistance. With an IP66 protection rating, it operates stably even amid dust and moisture.

• Intelligent Operation and Maintenance: The LCD provides real-time data display, and the HART protocol enables remote debugging, reducing the need for frequent disassembly and maintenance. The aluminum alloy painted junction box balances protection and heat dissipation, lowering failure rates. Over the long term, operation and maintenance costs are significantly reduced, saving enterprises both money and hassle.

IV. Industry Applications: Precision Empowerment, Unlocking New Production Potentials From monitoring pipeline pressure in petrochemicals to measuring water levels in environmental monitoring; from ensuring stable parameters in sterile food and pharmaceutical production to maintaining high-pressure equipment in new energy sectors, the CPA Pressure Transmitter is reshaping industrial measurement and control logic:

It acts as a “pressure sentinel” in oil pipelines, providing early warnings for safety; a “liquid level manager” in sewage plants, precisely controlling drainage processes; and a “quality guardian” in pharmaceutical workshops, safeguarding production parameters for every batch of drugs... Its three core strengths—precision, adaptability, and durability—make it a “standard” for intelligent upgrades across industries.

As the wave of Industry 4.0 surges, measurement and control precision determines production efficiency. The CPA Pressure Transmitter, with its high-precision single-crystal silicon core, versatile adaptability, and durable and reliable performance, creates an intelligent measurement and control system for enterprises that is “visible, controllable, and manageable.” Choosing CPA means choosing a future of precise production—elevating pressure measurement and control from “barely sufficient” to “precision-driven,” equipping every production line with a “smart brain.”